A technology offering the best guarantees of industrial performance and energy efficiency.

The manufacturing process is characterized by 3 main steps.

-

The preparation of the pulp

-

Molding by suction onto molds where a uniform layer of cellulose fibers is deposited.

-

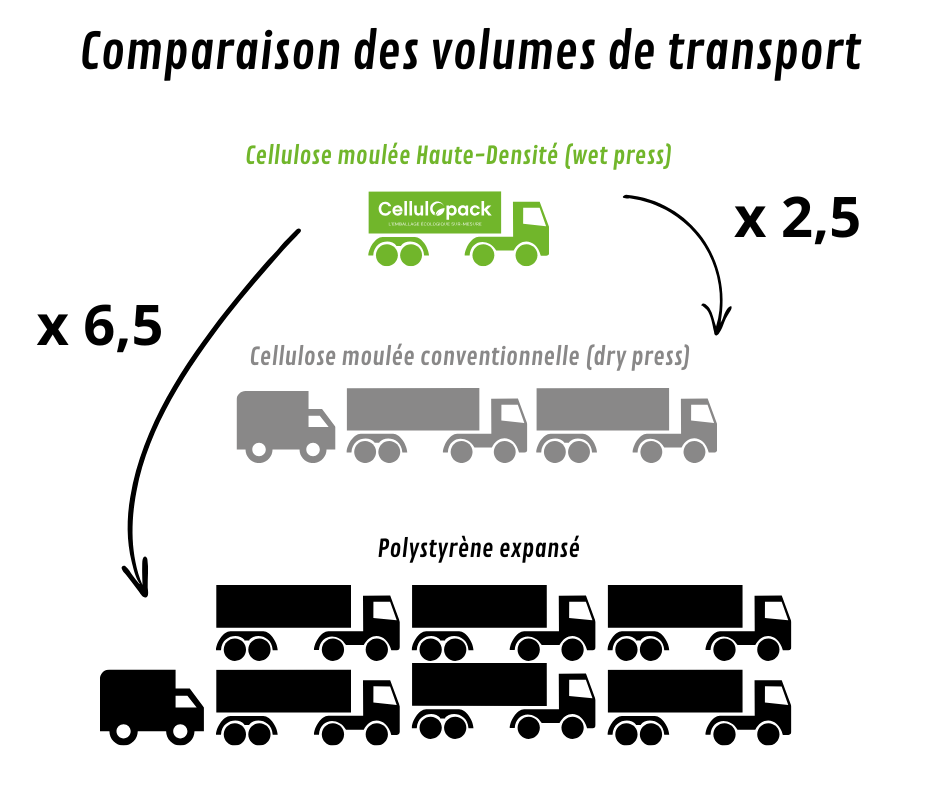

Drying – pressing of the packaging under high pressure between two heated forms and mechanically closed. This mechanical closing principle guarantees consistency in pressure settings. The pressure of several dozen tons prevents any deformation or shrinkage of the fibers during drying. This drying method ensures the preservation of dimensions up to 0.1 mm. A smoother surface and a more compact material allow storage gains of more than 50% during stacking compared to other molded pulp products (as well as transportation savings).

Innovative Tools for Highly Customized Products

Each project we undertake is based on the design of a custom mold by our design office, an essential investment to ensure a product perfectly suited to the specific needs of our clients. To go further, we also offer advanced options: a cutting tool for flawless finishes, ideal for food and premium packaging, and a lamination tool that allows the addition of a waterproof film, combining protection and aesthetics.

What are the advantages of CELLULOPACK products in High-Density Molded Pulp (HDMP)?

- A reduction in the material weight required, decreasing the carbon footprint.

- An excellent surface condition, which can be perfectly smooth.

- Optimized stacking with volume gains that can represent up to 7 times that of expanded polystyrene products.

- Significant storage and transportation savings.

- Very high dimensional precision of the packaging (+ or - 1/10 mm).

- Automation of packaging steps facilitated by automatic product depalletizing.

- Resistance to moisture, which can reach total impermeability depending on the client's requirements.

A refined manufacturing process to optimize logistics.

- A high-density product, more compact and thinner, which allows for optimized packaging and thus reduced transportation costs.

- Perfect rigidity thanks to long cellulose fibers from Kraft.

- Low moisture regain due to the appropriate treatment of the cellulose pulp.

Aesthetic Products

A smooth, ultra-resistant finished product for impeccable results!

CELLULOPACK uses a unique high-density molded cellulose manufacturing process. High density ensures a smooth surface, free from imperfections, enhancing both the touch and visual appeal of the product.

Ideal for premium packaging (luxury, cosmetics, electronics), they elevate brand image while offering optimal protection. Their dense and uniform finish also meets the requirements of the medical, high-tech, and premium food sectors, where quality and presentation are essential. Perfect for technical cushioning or design and decoration projects, these products combine customization, durability, and elegance, making them highly relevant across various industrial and commercial sectors.

Cellulopack SAS

Biodégradables, Compostables et Recyclables

197, Avenue de Lattre de Tassigny

82 100 Castelsarrasin

Contact Commercial : 06.22.19.85.95

Contact Usine : 09.72.43.13.59

Mail.

Nos 2 sites de production en France

CELLULOPACK

Usine de Campsas

23 rue Sepat

82370 CAMPSAS

CELLULOPACK

197, Avenue de Lattre de Tassigny

82100 Castelsarrasin